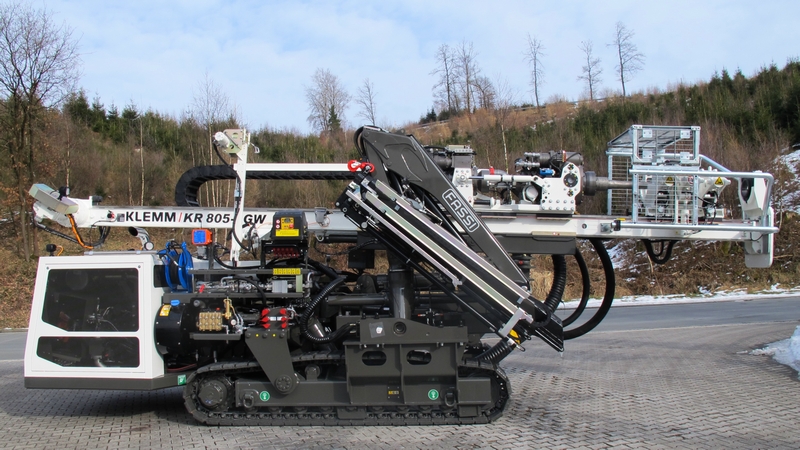

Heat-loop bores for shallow geothermal energy

Safe operation

The radio remote control of the drilling rig for all drilling, tramming and set-up functions is in accordance with EN 16228, making ergonomic operation and the best possible view of the drilling spot point and the danger zone. The geothermal drilling rig complies with EN 16228, and the "SPM" mode (Special Protective Mode) is available for working without an interlocking guard under special circumstances, and the "ROM" mode (Restricted Operation Mode) for manually changing the drill rods.

Energy-efficient work

As with almost all KLEMM drilling rigs, the Energy Efficiency Package (EEP) is also included as standard here. The drilling rig adapts automatically to the respective situation where it is used and utilises its potential power to a maximum. This significantly reduces fuel consumption and noise emissions.

Flexible use

With the oscillating tracks installed as standard and flexible kinematics, the machine can also be used very efficiently on uneven surfaces and built-up environments.

Powerful hydraulics

The hydraulic system rests on a load-sensing double pump and a volume flow control independent of the load. For this new development, the operating pressure for drilling functions was increased to 350 bar.

High drilling power

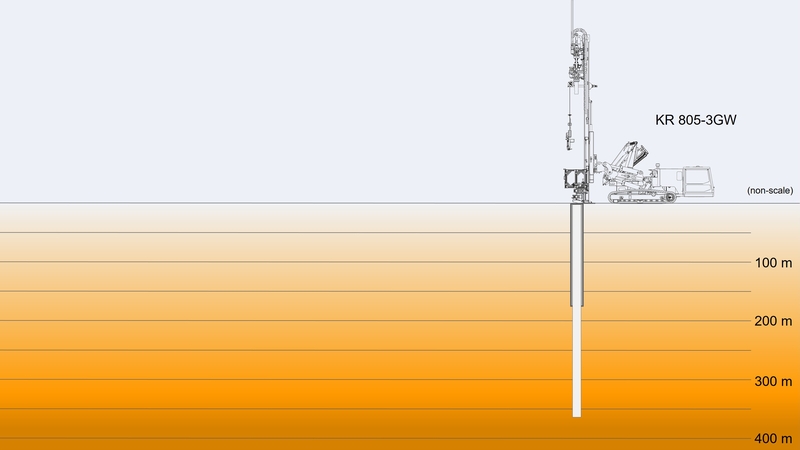

In combination with the engine power of 160 kW (or optionally 175 kW) and the increase of the operating pressure, the pump performance for faster drilling progress has been increased as compared with previous models. Casedheat-loop bores significantly over 300 m depth are possible.

Comprehensive additional equipment

The drilling rig is prepared for guidance and discharge of drill backflow and cuttings, for handling of the drill rod and the casing, for the handling of probes and for much more tasks particular to geothermal drilling (Standard and options).

Quality

Machines designed for longevity and easy of maintenance, in tried and tested KLEMM quality.

The advantages

Can be adjusted to the task at hand

- Loading crane or hydraulically erectable drill rod magazine

- Double head drilling unit with geothermal flushing and backflow preventer

- Rod handling system HBR 180-1

- Plastic- or rubber coated grouser plates

- Water pump, compressed air lubricator, washer, silencer

- Power outlet for external hydraulic additional consumers

- 3-part clamping and breaking device with hydraulic recovery function

- Biodegradable hydraulic oil and bypass flow filtration

KLEMM Benefits

Technical data

Chassis type | Oscillating crawler tracks | ||

Crawler components | B1 | ||

Width | 2,300 mm (2,460 mm w/ console) | ||

Tractive force max. | 148 kN | ||

Crawler speed | 2.0 km/h | ||

Chain width | 400 mm (3-rib) | ||

Oscillating range | +13 / -13 deg | ||

Ground clearance | 335 mm | ||

Ground pressure* | 88 kN/m2 | ||

Gewicht Bohrgerät | 19.5 | ||

*) Ground pressure of the machine with even weight distribution, taking the total weight into account |

Application range

- Drilling depths up to 375 m

- Casing depth up to 175 m

- Drilling system 152 / 89 mm

(depending on soil conditions)

Do you need support?

Martin Bonzel

Regional Sales

Region: North America